Water pumps and water storage tanks

February 7, 2017

Water storage tanks

February 8, 2017Hydraulic rams

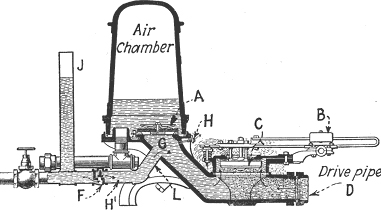

Hydraulic rams are pumps which are actuated by water power. They may be used for raising flowing water to a height greater than its own level, or water of unsatisfactory quality can be used to raise water of a satisfactory quality from a nearby spring to any reasonable elevation desired. A hydraulic ram is illustrated. Where the ram raises only its own water supply, pipe L and everything to the left of it do not exist.

Hydraulic rams are pumps which are actuated by water power. They may be used for raising flowing water to a height greater than its own level, or water of unsatisfactory quality can be used to raise water of a satisfactory quality from a nearby spring to any reasonable elevation desired. A hydraulic ram is illustrated. Where the ram raises only its own water supply, pipe L and everything to the left of it do not exist.

Under these conditions it operates as follows: Water enters the ram through the drive pipe and wastes out of the ram through the valve C. The water gains such velocity that valve C is suddenly slammed shut by the flowing water. The sudden closing of the valve creates sufficient pressure through water hammer to force valve A open, thus discharging a small quantity of water through the discharge valve A.

The air chamber on the discharge pipe prevents the development of a high pressure in the discharge pipe and reduces the fluctuations in the rate of discharge. After the pressure impulse resulting from the closing of the valve C has been expended there is a tendency for the water to surge backward up the drive pipe.

This surge opens a small air valve H, and admits a small quantity of air which is required to replenish the air in the air chamber. The surge, with the aid of weight B, also serves to open valve C. Valve A is automatically closed by the pressure of the water in the discharge pipe. The cycle of action is repeated indefinitely.

When pipe L is connected as shown, the ram will pump one quality of water by means of another quality of water. The pure water at H comes from a source at least 18 in. higher than the less pure supply at D. When valve C is open impure water is wasting from it and pure water is flowing through the check valve at F into the drive chamber at G and is also wasting through valve C. When valve C slams shut valve F is also shut and pure water passes through the valve at A. There is thus a slight waste of pure water through valve C but no impure water passes through valve A.

In the selection of a hydraulic ram the information which must be obtained includes: (a) the rate of flow of water during various seasons of the year, (b) the demand for water during the corresponding periods, (c) the available fall of the water for driving the ram, (d) the height of the desired lift, and (e) the greatest possible length of drive line. The length and diameter of the drive pipe are important because upon them depends the success of the ram.

The lower the available driving head the longer and larger must the drive pipe be. In general, the length of the drive pipe is about seven times its fall; it may vary between five and ten times, depending upon the conditions of delivery. The diameter of the drive pipe is usually about twice the diameter of the delivery pipe. The design of hydraulic rams requires special knowledge and experience with them. It should not be attempted by an inexperienced person. In general, rams will operate with a minimum drop of 3 ft. in the drive pipe and with a minimum drive supply of 3 gal. per minute.

The ratio of water delivered to water wasted depends on the fall and size of the drive pipe and the height of the lift. The best performances have shown an efficiency of 90 per cent.

Centrifugal pumps

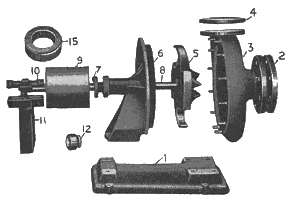

Centrifugal pumps are well suited to use for small water supplies, as well as for large supplies, because of the simplicity of their parts, the simplicity of their operation, and their " fool-proof " qualities. The simplicity of the parts of a centrifugal pump is illustrated. In operation the water enters the pump casing at the centre, point 2 in the figure, where it encounters some rapidly revolving vanes on the runner. The velocity of the water is greatly increased as it starts to travel around with the vanes. The centrifugal force thus brought into action forces the water rapidly and with an increasing velocity to the periphery (outer edge) of the revolving vanes, called impeller blades. Here the velocity of the water is reduced in the discharge channels and the velocity energy is changed to pressure. The blades of the impeller do not push the water out of the pump as the blades of a paddle wheel push a boat along. The design of centrifugal pumps requires special knowledge of hydraulics, mechanics, and the actions which take place in the pumps. The limitations and operations of the pumps should be understood, however, in order that the proper pump may be selected for any particular service.

Centrifugal pumps are well suited to use for small water supplies, as well as for large supplies, because of the simplicity of their parts, the simplicity of their operation, and their " fool-proof " qualities. The simplicity of the parts of a centrifugal pump is illustrated. In operation the water enters the pump casing at the centre, point 2 in the figure, where it encounters some rapidly revolving vanes on the runner. The velocity of the water is greatly increased as it starts to travel around with the vanes. The centrifugal force thus brought into action forces the water rapidly and with an increasing velocity to the periphery (outer edge) of the revolving vanes, called impeller blades. Here the velocity of the water is reduced in the discharge channels and the velocity energy is changed to pressure. The blades of the impeller do not push the water out of the pump as the blades of a paddle wheel push a boat along. The design of centrifugal pumps requires special knowledge of hydraulics, mechanics, and the actions which take place in the pumps. The limitations and operations of the pumps should be understood, however, in order that the proper pump may be selected for any particular service.

- 1. Base

- 2. Suction companion flange

- 3. Volute with studs

- 4. Discharge companion flange

- 5. Runner

- 6. Cover

- 7. Gland

- 8. Shaft

- 9. Pulley

- 10. Box cap

- 11. Bracket box

- 12. Set collar for type A or B

- 15. Horizontal ball bearing

There are two types of centrifugal pumps: one is known as a volute pump and the other as a turbine pump. In a volute pump the water leaving the impeller is discharged into a volute or snailshell-shaped casing the cross-sectional area of which increases directly as the increase in the quantity of water flowing through it, thus maintaining a constant velocity of discharge. In a turbine pump the casing of the pump is circular in shape and the impeller is surrounded by diffuser ribs forming water passages which gradually enlarge, slowing down the velocity and converting velocity energy into pressure.

The volute pump is simpler, less expensive, and better suited for small sizes. The turbine pump is more efficient and is found more often among the larger centrifugal pumps.

There is no practicable limit to the capacity or pressure which can be obtained in centrifugal pumps. As the pressures increase the speed of revolution or the size of the impeller, or both, may increase; or the number of impellers may be increased, the impellers being so arranged that the discharge from one enters the suction of the other.

Pumps with two or more impellers, one discharging into the other, are known as multi-stage pumps. The exact dimensions, speed of revolution, etc., of a pump for any particular service is fixed by the manufacturer. No simple rule is available by which the purchaser can determine the probable performance of a pump from its measurements.

The capacity can be approximated by assuming that the velocity in the discharge pipe is 10 ft. per second and multiplying this velocity by the cross-sectional area of the discharge pipe.

The efficiencies of centrifugal pumps in domestic water supply service is relatively low. Unfortunately, even such low efficiencies are not attained unless the pump is designed for the particular service to which it is to be put. The efficiency of a centrifugal pump will vary materially with the rate of discharge, the pressure, and the speed of revolution.

These relations are known as the characteristics of the pump. The most desirable pump, from the point of view of efficiency, to select for any particular service, is a pump in which the characteristics show the efficiency remaining approximately constant under the normal variations of operation. If economy of operation is to be considered the characteristics of the pump should be determined by test before purchase, or should be specified in the purchase agreement and later subjected to test. Such conditions are seldom enforced in the purchase of small pumps, the reputation of the manufacturer and his guarantee being relied upon without further test.

The material of the pump can be investigated by the purchaser before purchase. Standard-fitted centrifugal pumps are equipped with a cast-iron casing, steel shaft, bronze shaft sleeves (if any), a cast-iron impeller, and cast-iron diffusion vanes (if any).

Such pumps are suitable for ordinary service when moving non-corrosive liquids. Pumps handling sewage or corrosive liquids should be bronze fitted or all bronze or should be made of special composition to resist the effect of the particular liquid pumped. Bronze-fitted pumps have a cast-iron casing, steel shaft, bronze shaft sleeves, bronze impeller, and bronze diffusion vanes (if any). All bronze pumps have all parts, which are in contact with the liquid, made of bronze except that a bronze-covered steel shaft or a monel metal shaft may be used.

Centrifugal pumps are classed as high-speed machines. The smaller sizes are, therefore, usually driven by electric motors, either belt, gear, or directly connected to the pump. Gasoline or steam engines are less frequently used. Where the electric motor and the pump are on the same shaft the speed of the motor and the pump must be the same, and a flexible connection must exist in the shaft between the motor and the pump.

This connection will allow for only a slight eccentricity due to improper alignment of the shaft. Where the pump and motor are connected by a belt or gear train the two machines need not have the same speed the gear ratio or the diameter of the pulleys being relied upon to adjust the speeds of the pump and motor. For example, if the speed of the pump is 690 r.p.m. and that of the motor is 1,140 r.p.m. the diameters of the pulleys should be in the ratio of 1,140 ÷. 690 = 1.65, the larger pulley being on the slower-moving machine. That is, a 3-in. pulley on the motor will call for a 5-in. pulley on the pump under the above conditions.

The Hydraulic Society recommends that electric motors under 100 hp., rated on a 50° F. basis, have an extra margin of capacity of at least 20 per cent above the horsepower required by the pump. This recommendation is made to eliminate the chances of trouble from overheated motors as a result of possible deterioration, variation in operating conditions, location in overheated places, etc.

Troubles resulting from the setting of a centrifugal pump can best be avoided by bolting the pump down to a firm concrete foundation and arranging the suction pipe as short and as straight as possible. The discharge pipe should be equipped with a check valve and a gate valve, the former being nearer to the pump. If any suction lift is required the suction pipe should be equipped with a foot valve and provision should be made for priming the pump.

This can be done in any of three ways:

- By a by-pass around the gate valve which will admit water from the discharge pipe into the pump

- Bby an independent supply from some other source than the pump

- By the operation of a steam ejector or other vacuum pump on the suction line.

Rotary pumps

Rotary pumps resemble centrifugal pumps in outward appearance, in operation, in the manner of their setting, and in the motors used to drive them. In principle of operation they differ materially, however, from centrifugal pumps as they are distinctly displacement pumps, i.e., the blades of the rotor push the water through the pump. A cut through a rotary pump is shown. The blades of the rotor fit tightly together and to the casing. As the blades revolve water is displaced from the pump casing and is pushed through the discharge pipe. A high vacuum is created because of the tight fitting moving parts.

Rotary pumps have about the same efficiencies as centrifugal pumps in the smaller sizes but lower efficiencies than large-size centrifugal pumps. Although rotary pumps have no valves, the close fit of the rotor blades make them suited only to the pumping of liquids free from suspended solids. They are less fool-proof than centrifugal pumps because the closing of the discharge valve while the pump is in operation will result in damage to some part of the pumping equipment.

Rotary pumps are self-priming and no foot valve is required on the suction line. The same care in the setting of the pump is required as in the setting of a centrifugal pump and a check and gate valve should be placed on the discharge line.

Air-lift pumps

Air-lift pumps are used principally in well pumping. They have the advantage over all other types of well pumps in the simplicity of their parts and in that there are no moving parts in the well. They are able to discharge more water from a well of small size than any other type of pump, provided the water is available in the ground. They give long service, low maintenance cost, and great reliability.

Their efficiency is low, however, and they usually necessitate digging the well deeper than would otherwise be required because of the necessary submergence of the end of the air pipe, known as the foot piece. If the water must be raised to an appreciable height above the ground surface, additional pumping equipment is desirable at the surface as the air lift is not suitable to the discharge of water under high pressure.

The aeration of the water may increase its corrosiveness or it may be advantageous by precipitating dissolved minerals, such as iron, from the water. The efficiencies of air lifts are in the neighbourhood of 25 to 33 per cent, the higher efficiencies being secured at the lower lifts.

The use of an air lift should be limited to conditions where efficiency can be sacrificed for the sake of reduction in maintenance expense or it is desired to increase the output of a well, greater reliability is desired than would be obtained through some other available equipment, or where the well is too crooked to permit of the use of rods or shafting in the well, or the water must be lifted more than about 200 ft. in the well.

Compressed air enters the bottom of the discharge or eductor pipe through a diffuser apparatus called the foot piece. The water is partly blown out of the well by the rising air bubbles acting as pistons and is partly lifted from the well because the weight of the column of air and water is balanced by the weight of the solid column of water outside of the well.

In order to lift the water from the well there must, therefore, be a considerable height of water outside of the well or, in other words, the foot piece must be deeply submerged.

The equipment of an air lift includes an air compressor, an air receiver for storing compressed air to make the operation of the compressor and air-lift smoother, the necessary air piping, and a foot piece to distribute the air in small bubbles at the bottom of the eductor pipe.

By the addition of a "booster" on the upper end of the eductor pipe the air is separated from the water and the pressure of the air and the kinetic energy of the high velocity of the water issuing from the well are converted into pressure to raise the water to a higher elevation. The compressed air is released from the booster through a valve, which is throttled by trial, to obtain the best operating conditions.

Hydropneumatic pumping equipment

A combination of an automatically operated electric motor and a small pneumatic pressure tank. Where electricity is not available gasoline motors can be installed but the advantage of automatic operation is lost, and larger pneumatic storage tanks must be used.

When the pump is not operating, the expansion of the air in the pneumatic tank is sufficient to raise the water to the desired height. When the air pressure is so reduced as no longer to discharge the water or to cut down the flow materially, the electric motor is automatically put into operation thus restoring the water pressure.

The opening of a faucet anywhere in the plumbing system of the building will reduce the pressure in the pneumatic tank so as to throw the motor into operation and force water directly into the piping system. The pumps on such devices operate on either the reciprocating, centrifugal, or rotary (displacement) principle. Most of such devices on the market are patented and can be obtained directly from- the dealers. They are very satisfactory and give good service.

Units are available in practically all capacities from one gallon up to 400 gal. per minute. The capacity of the pneumatic tank should not be less than 30 gal. for a five-fixture installation. The capacity should be increased in proportion to the additional fixtures but beyond 70 gal. the capacity of the tank need not be increased for household supplies.

In any installation, the pump should not be thrown on and off more often than about once in 15 to 30 min. The pneumatic tank should, therefore, have a storage capacity equal to approximately 30-min. use, or thirty times the amount of water thrown by the pump in 1 min.

Computation of suction and discharge lift

In selecting the capacity and in determining the location of a pump the suction and discharge lifts are important considerations. This information should be furnished by the purchaser to the pump manufacturer. The total lift, discharge head plus suction lift, includes the difference in elevation between the free surfaces of the water at the source and at the point of discharge; all losses of head due to friction, entrance, etc.; and the velocity head in the suction pipe and the discharge pipe.

The entrance loss for a pipe flush to the face of a wall, as shown in A, is assumed to be one-half a velocity head. If the suction pipe protrudes into the reservoir, as shown in B, the loss is one full velocity head, and if the pipe is arranged as in C some amount between one-half and one full velocity head is assumed.